In the dynamic landscape of industrial manufacturing, the volumetric filling machine stands as a pivotal player, orchestrating the precise dispensing of liquids and granular substances. Its significance reverberates across various sectors, from food and beverage to pharmaceuticals and chemical manufacturing. To comprehend the depth of its impact, let us delve into the intricate world of volumetric filling machines.

Working Mechanism

At its core, the volumetric filling machine operates on the principles of accuracy and consistency. It relies on volumetric measurement, ensuring that the exact volume of a substance is dispensed with each cycle. This is achieved through the ingenious utilization of pistons or cylinders, which meticulously measure and transfer the desired quantity.

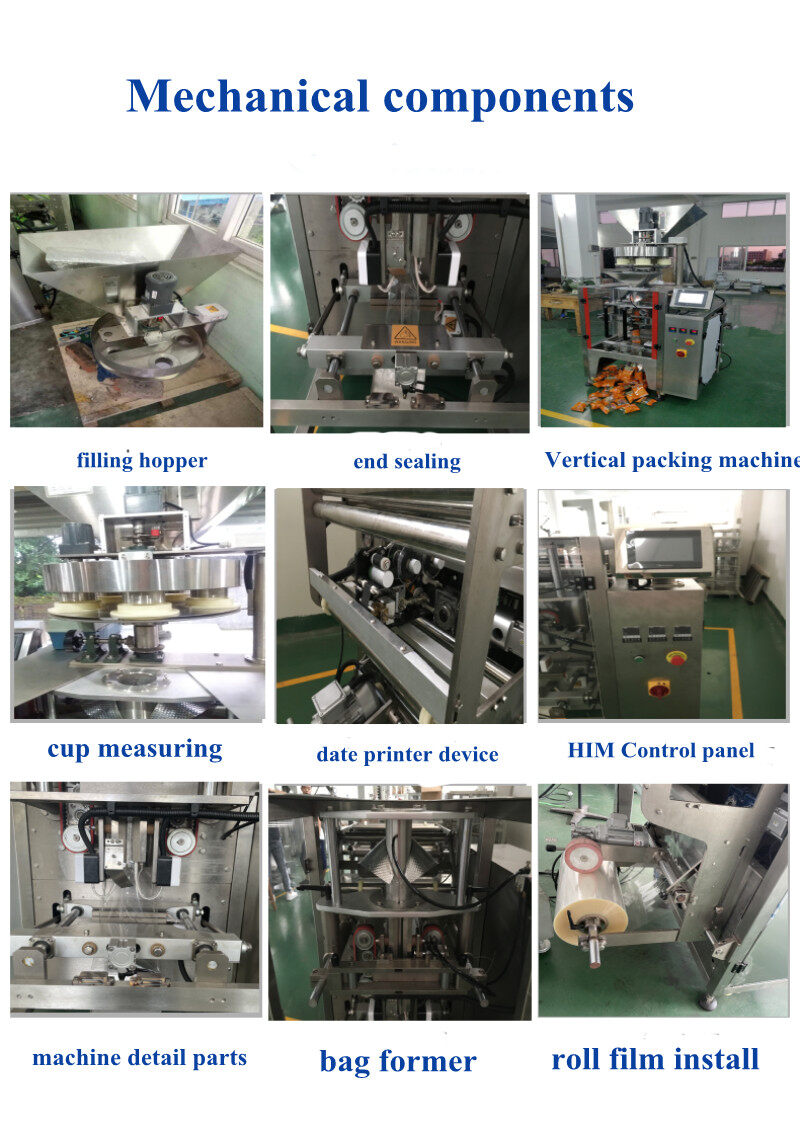

Components and Their Functions

Piston or Cylinder

The key to the volumetric filling machine lies within its pistons or cylinders. These components move with rhythmic precision, displacing a specific volume of substance in each stroke. The calibration of these pistons determines the accuracy of the entire filling process.

Nozzles and Valves

A coordinated dance of nozzles and valves directs the precise release of substances into containers. These components regulate the flow, prevent spillage, and ensure a seamless transfer from the machine to the awaiting receptacle.

Control Systems

The control systems manage the entire process - from regulating the speed of filling to monitoring the accuracy of measurements; these systems ensure a harmonious symphony of precision.

Applications Across Industries

Food and Beverage

Liquid Products: Volumetric filling machines find a natural home in the production of liquid goods. From juices to sauces, the accuracy of dispensing ensures that every bottle contains the promised quantity, meeting both consumer expectations and regulatory standards.

Granular Substances: The versatility of these machines extends beyond liquids to granular substances. Whether it's rice, sugar, or coffee, the volumetric filling machine ensures that each package contains the intended volume, contributing to efficient packaging processes.

Pharmaceutical

Precision in Medication Dosage: In the pharmaceutical realm, where precision is paramount, volumetric filling machines play a crucial role in ensuring the accurate dispensing of medications. This not only adheres to stringent regulatory requirements but also fosters trust in the reliability of pharmaceutical products.

Compliance with Regulatory Standards: Regulatory compliance is a constant drumbeat in the pharmaceutical industry. Volumetric filling machines provide a robust solution, allowing manufacturers to meet and exceed regulatory standards, thereby bolstering the quality and safety of medicinal products.

Chemical and Petrochemical

Handling Hazardous Materials: Dealing with hazardous materials requires not just precision but also safety. Volumetric filling machines, designed with the intricacies of chemical handling in mind, offer a controlled environment for the dispensing of potentially dangerous substances.

Ensuring Accuracy in Chemical Blending: In chemical processes where the right mixture can make or break a product, volumetric filling machines shine. They contribute to the accuracy of blending processes, ensuring that the chemical composition meets exact specifications, a critical factor in industries where consistency is king.

Advantages and Challenges

Precision and Efficiency

Minimizing Wastage: One of the primary advantages of volumetric filling machines lies in their ability to minimize waste. Precise measurements mean that every drop or granule contributes to the final product, reducing both environmental impact and production costs.

Improving Production Speed: Efficiency is crucial to industrial processes, and volumetric filling machines quicken that pulse. By automating the filling process with precision, these machines enhance production speed, contributing to higher output without compromising on quality.

Challenges in Implementation

Maintenance Considerations: Like any intricate machinery, volumetric filling machines demand meticulous maintenance. Regular checks, cleaning, and calibration are imperative to ensure that the precision they promise is consistently delivered.

Compatibility with Various Substances: The diverse nature of substances being dispensed poses a challenge. Volumetric filling machines must be versatile enough to handle liquids with varying viscosities and granular substances of different densities, demanding engineering solutions that accommodate this diversity.

Conclusion

The volumetric filling machine stands as a testament to the marriage of precision and efficiency in industrial processes. From the controlled release of pharmaceuticals to the seamless packaging of granular goods, these machines are the unsung heroes of manufacturing, ensuring that what is promised is precisely what is delivered. If you want more info about the high-performance volumetric filling machine, please feel free to contact us at sales3@fsxkl.com.

.jpg)

.jpg)