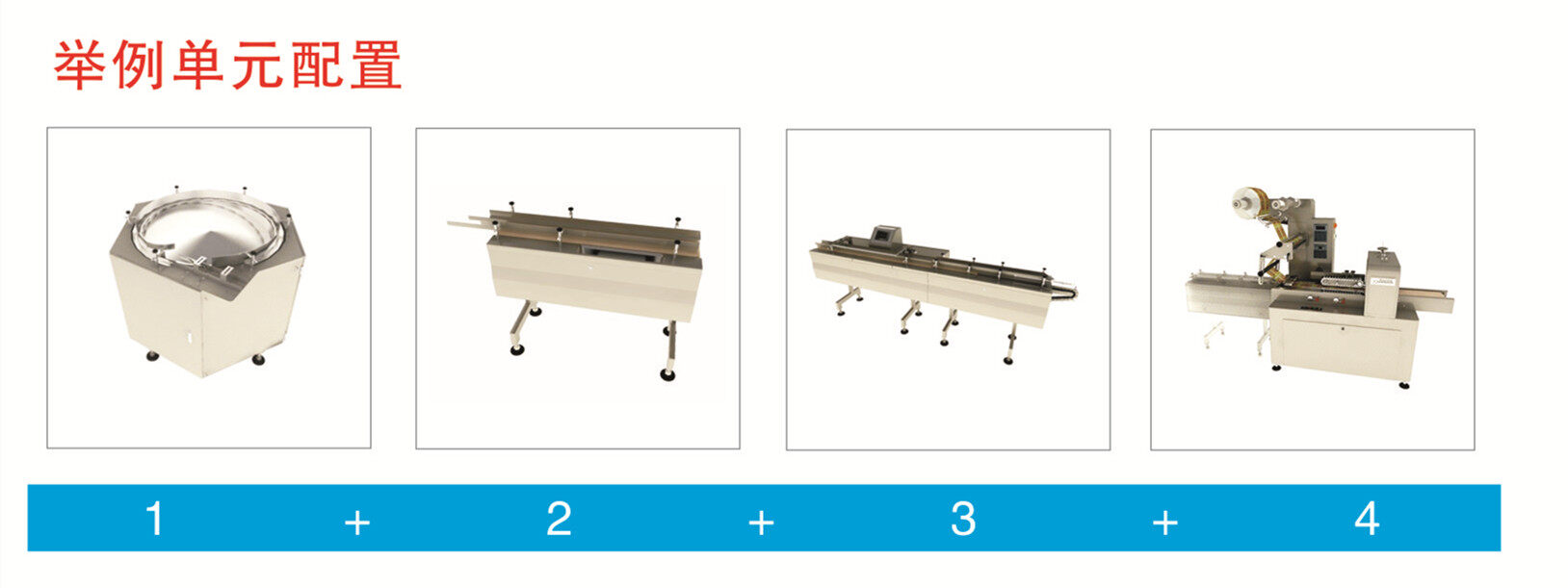

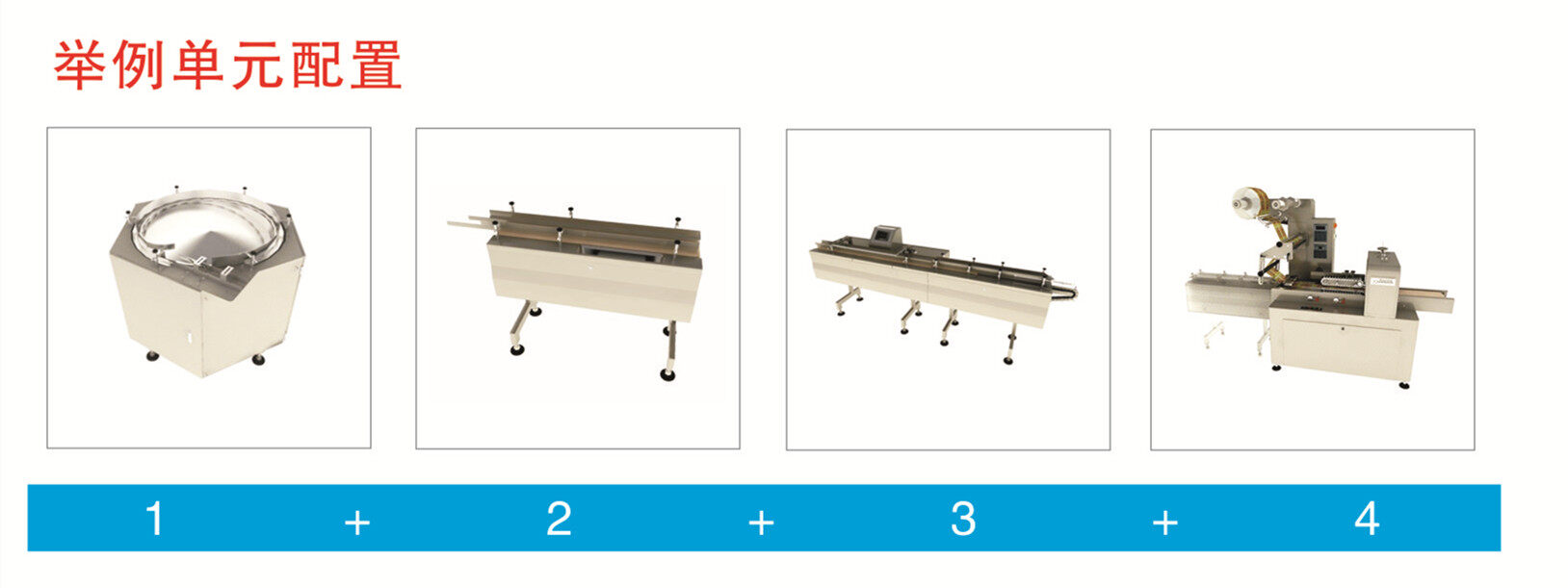

Machine Functions

Main performance and structural features:

1. The rice noodle automatic material

processing line consists of a feeding conveyor, a disc finishing machine, an

automatic material handling unit and an automatic packaging machine. The

centrifugal force of the disc is used to sort out the rice and other products,

and the products are sent in an orderly manner. The material handling unit is

positioned and packaged. It achieves the effects of continuous, orderly

production, low scrap rate and beautiful packaging.

2, a single line packaging speed of up to

150-350 packets / minute.

3. The whole line adopts 220V 50HZ power

supply. As shown in the figure, the total power of one to two is about 11KW.

Advantage:

1. The disc organizes the materials, so

that the products are ordered into the material processing unit to achieve

smooth material transportation, accurate positioning and high speed and

stability.

2, the material conveyor belt can realize

quick disassembly and assembly without tools, and the slag trough is matched

under the belt and at the interface, which is convenient for maintenance and

cleaning, saving time and labor.

3, the overall structure is simple, easy

to operate, easy to clean, easy to maintain, different specifications of

product replacement adjustment and operation is simple, the parameter settings

are simple.

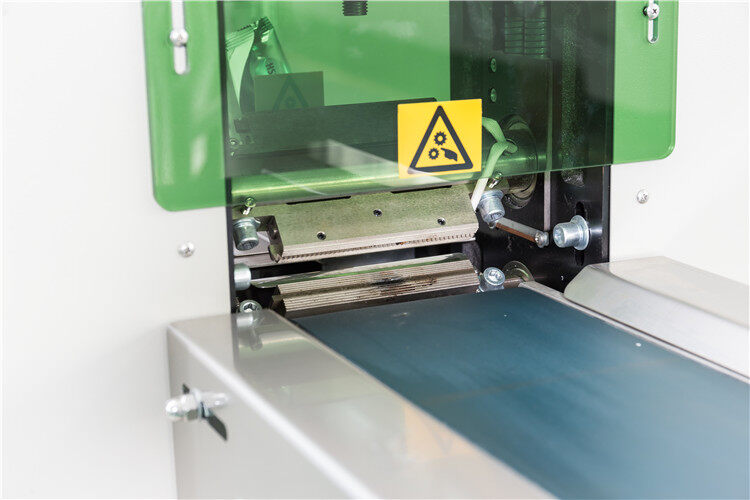

4. The conveyor belt is a food-grade blue

anti-bacterial PU belt, which can be equipped with anti-adhesive tape and white

PU belt.

5. The control system adopts high-quality

electrical components, intelligent PLC control, touch screen display, good

man-machine interface, simple, intuitive and convenient operation.