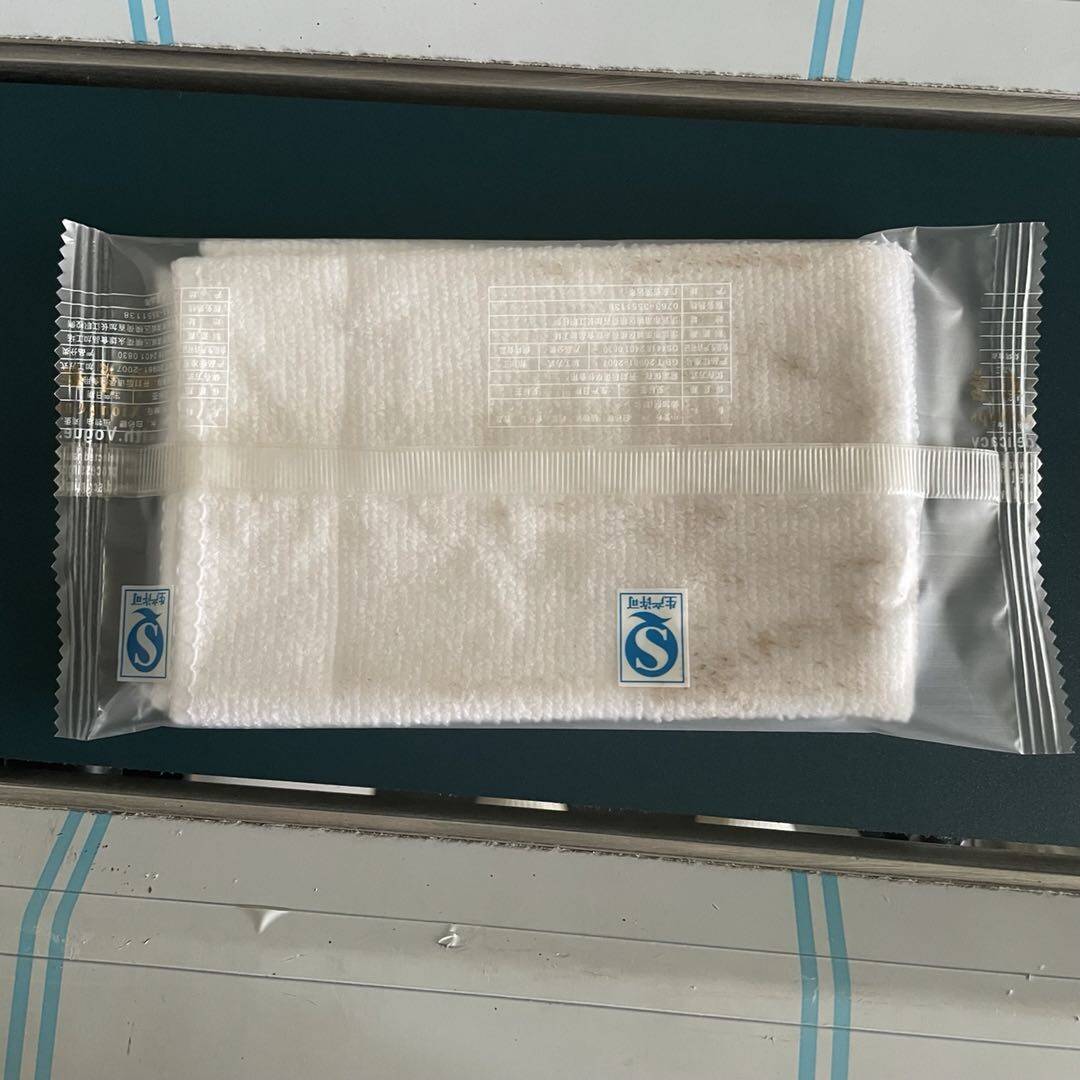

wet towel.wet wipes packaging machine pillow bag packing :

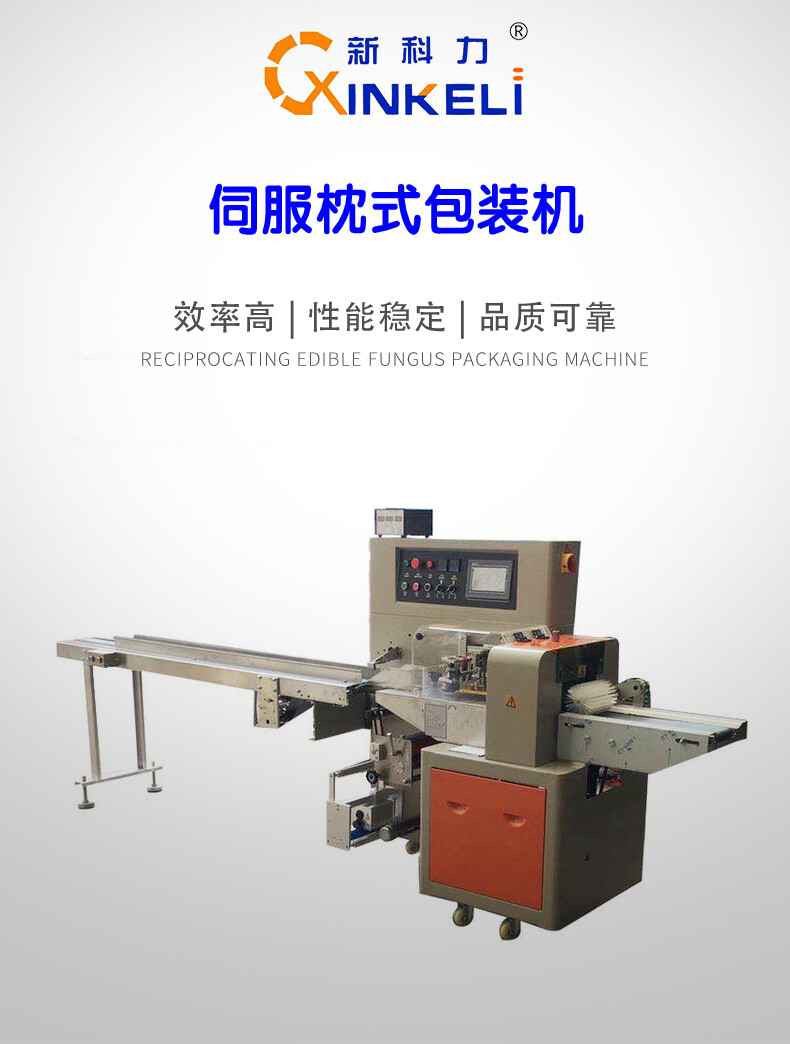

(a) wipes packaging machine pillow type Function and features:

1. Color touch screen display, PLC/computer control, automatic and fast photoelectric track.

2. The bag length without manually setting, machine could detect it automatically.

3. Machine has high performance, simple operation and fast packing speed.

4. Gear system besides double frequency converter controller, which making machine simpler operation, higher-speed

and stabler performance. It’s the first third-generation pillow type packing machine in China.

1. Color touch screen display, PLC/computer control, automatic and fast photoelectric track.

2. The bag length without manually setting, machine could detect it automatically.

3. Machine has high performance, simple operation and fast packing speed.

4. Gear system besides double frequency converter controller, which making machine simpler operation, higher-speed and

stabler performance. It’s the first third-generation pillow type packing machine in China.

(B)Non-woven clothes wipes packaging machine pillow type Specification

|

Model

|

KL-250X

|

|

Packing speed

|

35-120 bags/min

|

|

Width of film

|

100-250 mm

|

|

Making bag size

|

L 90-300MM; W 50-100; H 10-60 (mm)

|

|

Total power

|

2.4KW

|

|

Power supply

|

1 Ph. 220V, 50/60Hz

|

|

Machine size

|

L3770*W8000*H1550

|

|

Net weight

|

450kg

|

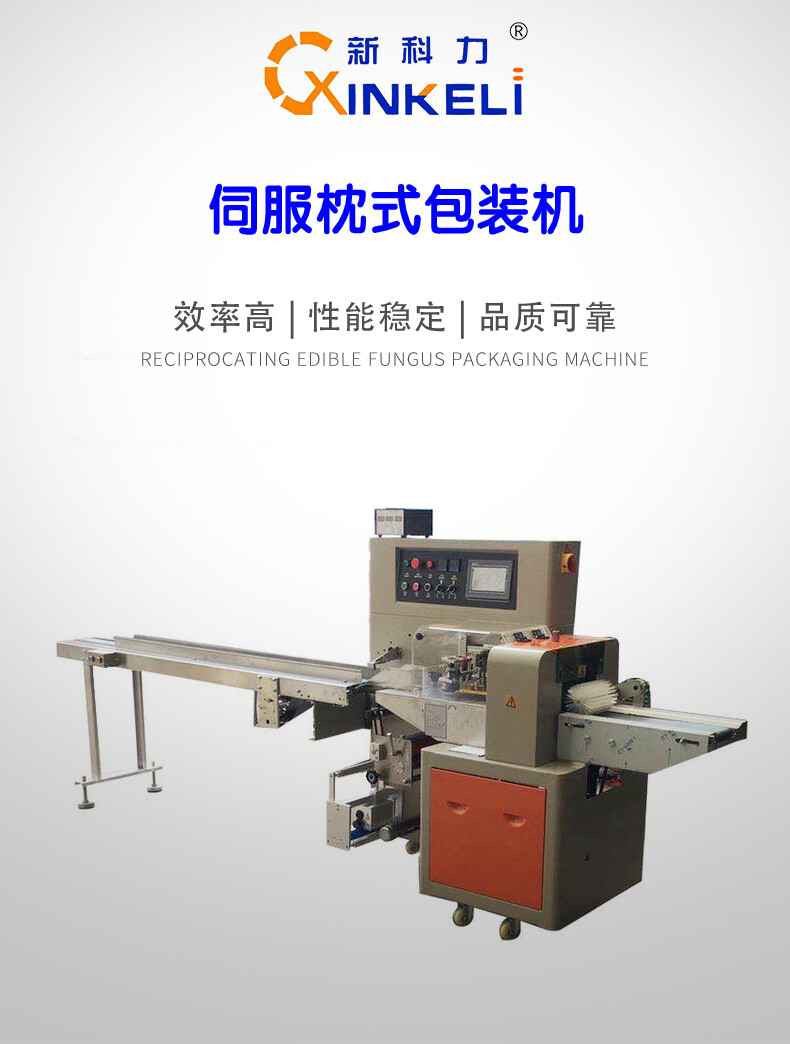

tissue wet wipes packaging machine Optional function/device:

3.1.No product machine stop function;

3.2 No cutting when product under knife function;

3.3 Nitrogen filling device;

3.4 Alcohol spraying device;

3.5 Gusseted bag device;

3.5 Full stainless steel body.

3.6 Servo motor;

3.7 PLC control.